Unlocking the Power of Molding Plastics in the Electronics Industry

The electronics industry is a dynamic and rapidly evolving sector, constantly pushing the boundaries of technology and innovation. At the forefront of this progress is Nolato, a pioneering company that specializes in the manufacturing of high-quality plastic components for various industries. In particular, their expertise in molding plastics has had a profound impact on the electronics sector.

The Significance of Molding Plastics

Molding plastics has become integral to the design, production, and functionality of electronic devices. By leveraging this technique, Nolato has revolutionized the manufacturing process, allowing for the creation of intricate and customizable components that meet the demands of today's technologically advanced world. Whether it's smartphones, wearables, or advanced medical electronics, molding plastics has played a crucial role in shaping the future.

Enhancing Design Flexibility and Customization

One of the key advantages of molding plastics in the electronics industry is the ability to enhance design flexibility and customization. Nolato's cutting-edge molding techniques enable the production of complex shapes, sizes, and textures, providing electronic manufacturers with limitless possibilities for product design. From sleek and ergonomic casings to intricate internal components, molding plastics empowers designers to create visually appealing and high-performing devices.

Optimizing Performance and Functionality

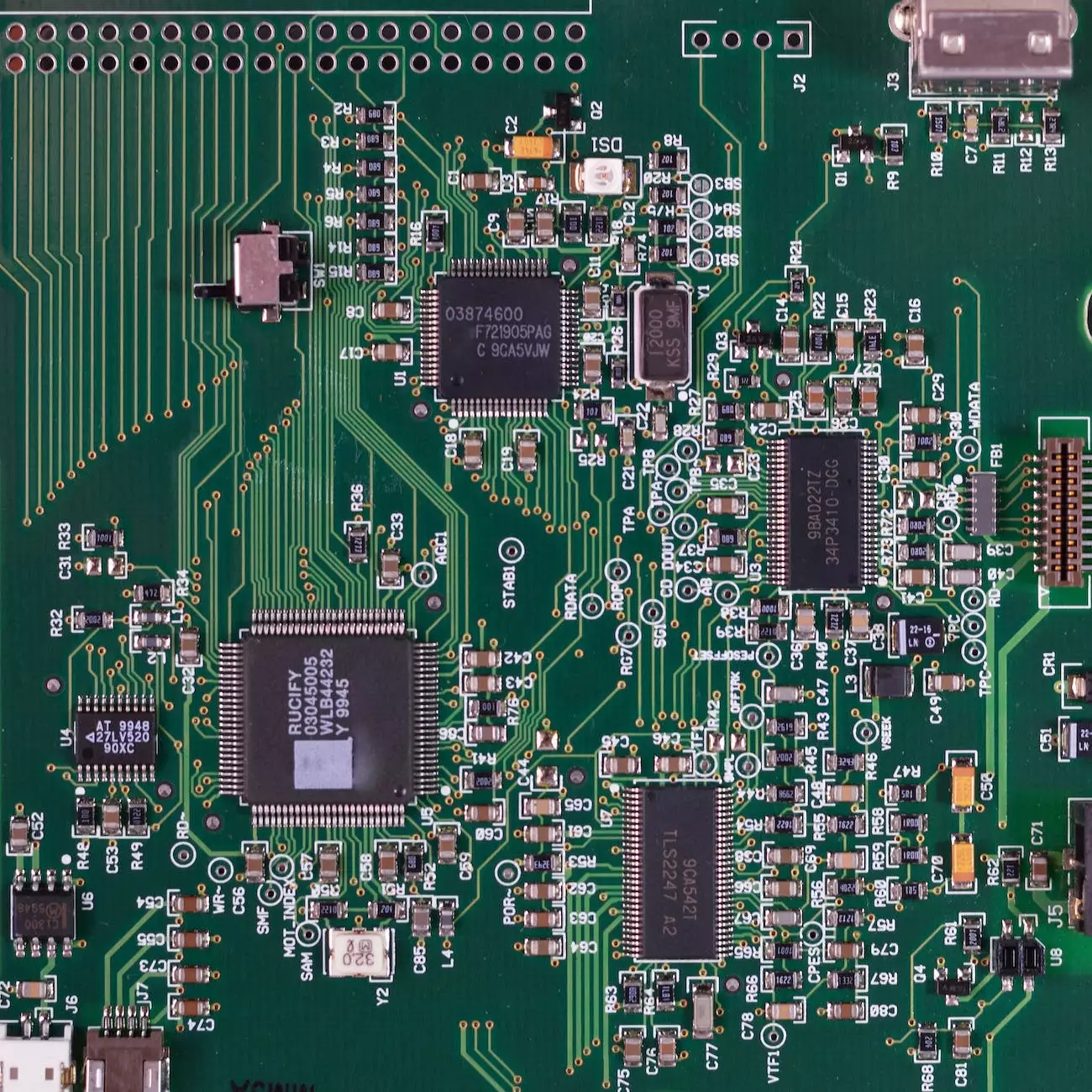

Molding plastics not only improves the aesthetic aspects of electronic devices but also plays a pivotal role in optimizing their performance and functionality. Nolato's expertise allows for the integration of various functional features directly into the molded plastic components. This includes precise cavities for microchips, connectors, and other electronic elements, ensuring seamless assembly and superior performance.

The Advantages of Choosing Nolato

When it comes to molding plastics for the electronics industry, partnering with a trusted and experienced company like Nolato is instrumental in achieving superior results. With over several years of experience in the field, Nolato has cemented its position as a leading provider of high-quality plastic components that drive innovation in the electronics sector.

Unparalleled Expertise and Cutting-Edge Technology

Nolato boasts a team of skilled engineers and technicians who are well-versed in the intricacies of molding plastics. Their expertise, combined with state-of-the-art facilities and cutting-edge technology, allows Nolato to deliver exceptional solutions that surpass industry standards. By leveraging innovative molding techniques such as injection molding, blow molding, and insert molding, Nolato ensures the highest levels of precision, efficiency, and quality.

Commitment to Sustainability

As the world becomes increasingly conscious of the environmental impact of various industries, Nolato firmly believes in sustainable practices. They prioritize eco-friendly materials and adhere to stringent environmental regulations throughout their manufacturing process. By choosing Nolato, electronic manufacturers can contribute to a greener future while delivering exceptional products to consumers.

Collaborative Partnership and Customization

At Nolato, fostering long-term collaborative partnerships with their clients is paramount. They understand that each electronic product has unique requirements, and thus, they provide tailored solutions to meet specific needs. From initial concept development to final production, Nolato works closely with their clients, ensuring seamless integration of molding plastics into the overall product manufacturing process.

Success Stories and Client Testimonials

Through their dedication to excellence and relentless pursuit of innovation, Nolato has built a remarkable track record in the electronics industry. Countless electronic manufacturers have witnessed the transformative impact of molding plastics on their products. Here are just a few success stories and testimonials from Nolato's satisfied clients:

ABC Electronics - Pioneering a New Generation

"Partnering with Nolato allowed us to pioneer a new generation of wearable devices. Their expertise in molding plastics enabled us to create lightweight and ergonomic casings without compromising on functionality. Our customers were thrilled by the seamless blend of design and performance, cementing ABC Electronics as a market leader in wearables."

XYZ Corporation - Driving Innovation Forward

"Nolato played an instrumental role in driving innovation in the medical electronics field. Their ability to mold intricate components to precise specifications allowed us to push the boundaries of what was previously thought possible. Thanks to Nolato's involvement, our medical devices have not only improved patient care but also revolutionized medical procedures."

Conclusion

In an era where technology reigns supreme, molding plastics has emerged as a game-changer in the electronics industry. Nolato's expertise and groundbreaking techniques have propelled the sector forward, empowering electronic manufacturers to create visually stunning, high-performing, and innovative devices. By choosing Nolato as your molding plastics partner, you gain access to unparalleled expertise, cutting-edge technology, and a commitment to sustainability. Embrace the power of molding plastics with Nolato, and unlock a world of limitless possibilities in the electronics industry.