The Engine Pump Water: An Essential Component of Diesel Engines

In the world of diesel engines, the term "engine pump water" refers to a critical system that plays a vital role in the overall functionality and efficiency of diesel engines. Understanding this component, its purpose, and its place within the larger category of diesel engine parts is essential for both enthusiasts and professionals alike.

What is an Engine Pump Water?

The engine pump water, commonly called the water pump, is a mechanical device within diesel engines that circulates coolant throughout the engine block. Its primary role is to manage the engine's temperature—ensuring it remains within optimal operating limits to enhance performance and longevity.

How Does the Water Pump Work?

The operation of the water pump is relatively straightforward yet crucial:

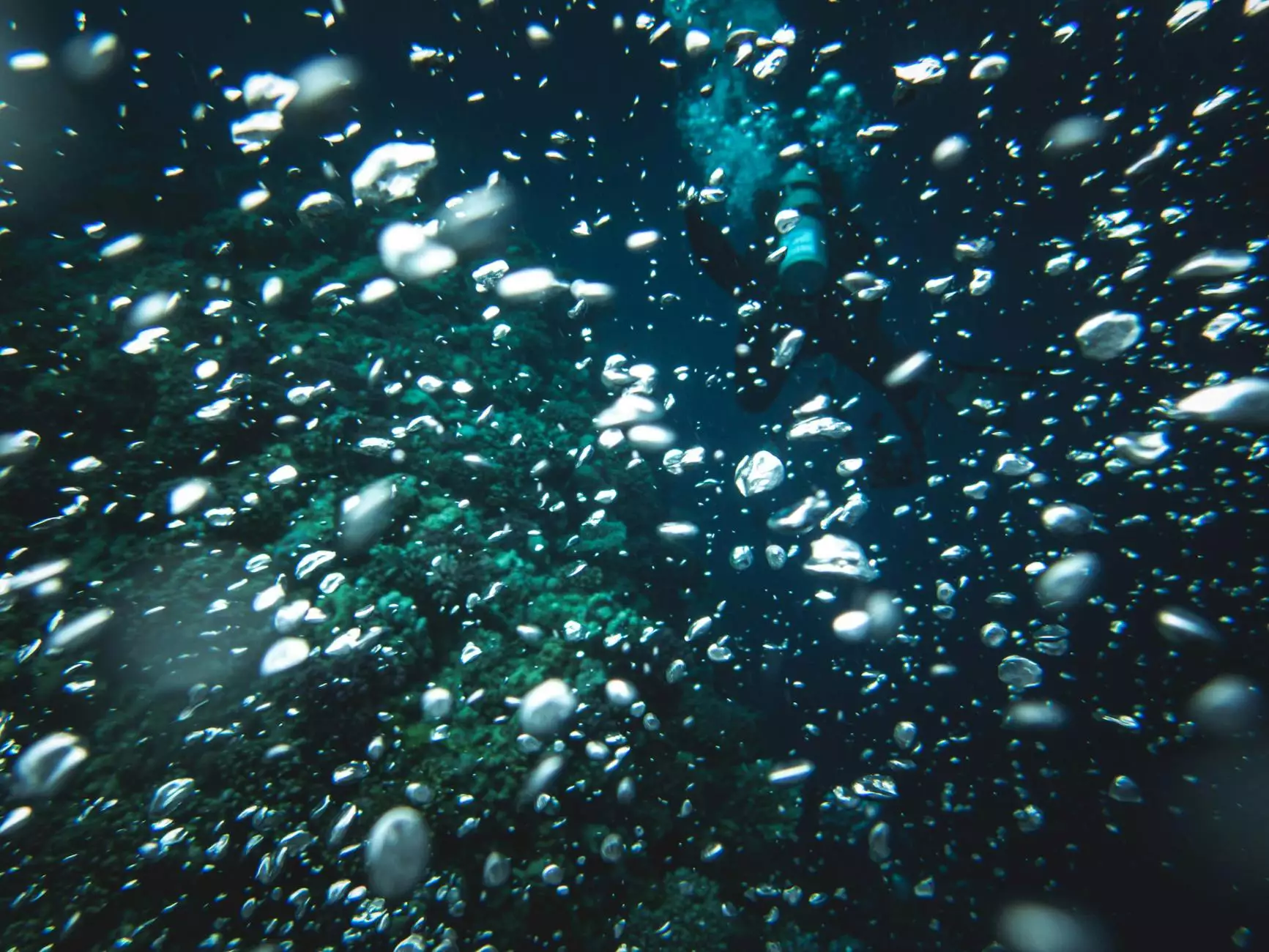

- Intake of Coolant: The pump draws coolant from the radiator through the intake side.

- Circulation: It then pushes the coolant into the engine block, where it absorbs heat generated during the combustion process.

- Return Flow: Finally, the heated coolant is returned to the radiator for cooling, thus completing the cycle.

Types of Engine Water Pumps

Various types of engine water pumps are available, each designed to cater to specific engine requirements and configurations. Understanding the types can help in selecting the right one for your diesel engine:

1. Mechanical Water Pumps

Mechanical water pumps are driven directly by the engine through a belt or timing chain. They are highly efficient and common in many diesel engines due to their simplicity and reliability.

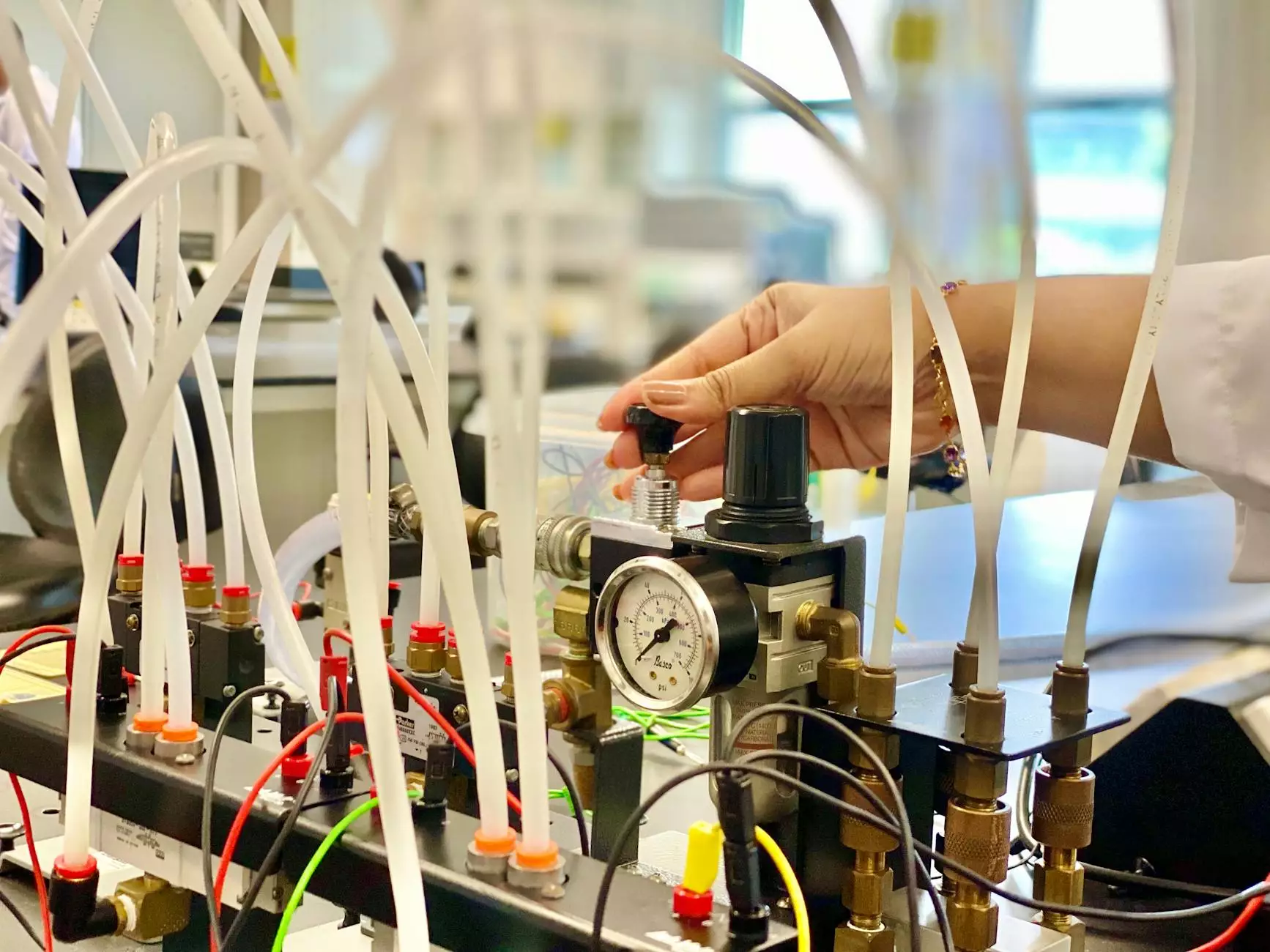

2. Electric Water Pumps

Electric water pumps, on the other hand, operate independently of the engine's mechanical systems. They can provide efficient cooling that adjusts based on actual engine temperatures, making them more effective in certain high-performance applications.

3. Valve Control Systems

Some advanced diesel engines employ valve control systems that control the flow of coolant more precisely, allowing for improved thermal management.

The Importance of Quality Water Pumps

Selecting a high-quality engine pump water is crucial for several reasons:

- Effective Cooling: High-quality pumps provide optimal flow rates, ensuring effective cooling and heating regulation.

- Durability: Quality parts resist wear and tear, extending the lifespan of both the pump and the engine.

- Reduced Maintenance Costs: Investing in dependable supplies minimizes the risk of breakdowns and subsequent repair expenses.

Signs of a Failing Water Pump

Understanding the signs of a failing water pump can save you from significant engine damage. Look out for the following indicators:

- Overheating Engine: If your engine frequently overheats, your water pump may be failing to circulate coolant.

- Leaking Coolant: Puddles of coolant under your vehicle signal possible water pump leaks.

- Unusual Noises: Grinding or whining noises from the engine may indicate a malfunctioning pump.

Choosing the Right Spare Parts Suppliers

When it comes to sourcing spare parts for diesel engines, picking the right supplier is paramount. Here's what to consider:

1. Reputation

Reputation is key when selecting a supplier for diesel engine parts. Research customer reviews and seek recommendations from industry professionals.

2. Product Quality

Ensure that your supplier offers OEM (Original Equipment Manufacturer) parts or high-quality aftermarket components for concurrent compatibility and reliability.

3. Customer Support

Opt for suppliers that provide exceptional customer service, offering warranties and straightforward return policies to guarantee your satisfaction.

4. Range of Products

A good supplier should have a comprehensive inventory, meaning you can find everything from engine pump water components to turbochargers and filters in one place.

The Future of Engine Water Pumps

As technology evolves, so does the engineering of engine pump water systems. Here are some trends shaping their future:

1. Smart Technology

Smart water pumps that integrate with IoT (Internet of Things) are becoming more prevalent. These pumps can monitor performance parameters and send alerts for maintenance needs, enhancing efficiency and reliability.

2. Hybrid Cooling Systems

With the rise of hybrid and electric vehicles, we may see advances in cooling technologies that combine traditional water pumps with electric systems for enhanced control.

3. Sustainable Materials

Environmental concerns are steering manufacturers towards using more sustainable materials, reducing waste, and enhancing recyclability.

Conclusion

The engine pump water is an essential element in maintaining the efficiency and longevity of diesel engines. By understanding its workings, recognizing the signs of failure, and choosing high-quality parts and suppliers, you can ensure that your diesel engine operates smoothly. For all your diesel engine parts needs, including the engine water pump, look no further than client-diesel.com, where quality meets reliability.